Foreign Companies Opting Out?

China Today, January 23, 2017 Adjust font size:

Opportunities under New Circumstance

Tapping into technology and experience to leverage China’s long-term development, rather than depending on certain preferential policies, is at the core of Siemens’ strategy in China’s market.

When the German government put forward its “industry 4.0,” the Chinese government proposed the “Made in China 2025” strategy. Although under different names, they have the similar mission of strengthening national competitive power amid constantly evolving industry. Guided by the industrial strategy, China aims to transform its labor-intensive industry into technology-intensive industry, and gain global competitiveness through providing digital solutions.

In June 2016, the German Chancellor Angela Merkel and Chinese Premier Li Keqiang witnessed the renewal by Siemens AG and China’s National Development and Reform Commission of the Memorandum of Comprehensive Cooperation between Machinery, Electric and Electronics Industries of the People’s Republic of China and Siemens AG. This renewal effectively broadened cooperation in the areas of intelligent manufacturing, intelligent infrastructure, and sustainable energy. In response to the “Made in China 2025” and “Internet Plus” strategies, Siemens AG has shared its “digital enterprise technologies and solutions” with China in order to boost transformation and upgrading of Chinese industries.

In the heart of China’s southwest city of Chengdu is a small old-town district, surrounded by concrete skyscrapers and multi-lane highways. There you can sample the spicy foods typical of Sichuan Province and observe a more relaxed lifestyle than that of Beijing.

Siemens Industry Automation Products Manufacturing and Development Base, or Siemens Electronic Works Chengdu (SEWC), has now commenced operations here. Thanks to its digitalization expertise, which is vast compared to the national average, companies are flocking to the region, as evident in the many high-tech manufacturers that have set up plants here. The local government is also establishing favorable conditions for start-ups, so attracting more investors. Chengdu stands testament to the fact that high-tech innovation in China is no longer the preserve of the capital Beijing or the major coastal cities of Shanghai and Shenzhen.

As a newly built digital factory, SEWC is a shining example of the Siemens industry automation products manufacturing and development system. The company is engaged in digital production and manufacturing, underlining that the world has entered the “industry 4.0” era. SEWC is Siemens AG’s third industry automation products R&D center, after that in Germany and the United States. It is also its first overseas “digital factory” outside Germany.

The CEO of Siemens Digital Factory Division Anton S. Huber commented that SEWC has been a strategic segment of Siemens AG’s global manufacturing system, not only selling products to the local market, but also providing high-tech products globally.

“You will hardly find a factory in China that operates at this level,” Dr. Beitinger from Germany said. Even though automation has made considerable progress in China’s industry, such high added value can be achieved only by precisely analyzing and optimizing core processes, step by step. This, Beitinger believes, is the prerequisite for a digital factory.

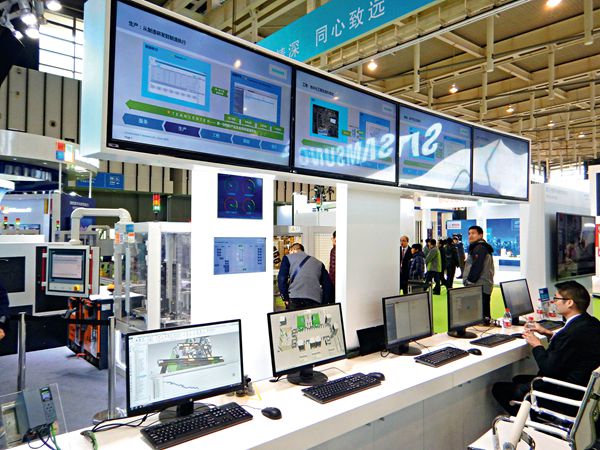

Siemens presents its digital interactive projects at the World Intelligent Manufacturing Summit in Nanjing, Jiangsu Province in December 2016.

The facility has more than 5,000 visitors every year. Delegations from major Chinese industrial operations come to SEWC to learn about the production of Simatic controllers and other electronic components. What interests them most is the facility’s successful implementation of the Digital Enterprise concept. SEWC production is digitally recorded, monitored, analyzed, and optimized.

China’s newly-introduced policies, including the Belt and Road Initiative, Made in China 2025, new urbanization, and intelligent manufacturing (to name but a few) offer new opportunities. “What we must do is readjust our business in accordance with China’s future development trend,” Herrmann said.

“For us, China’s market is big and has abundant investment potential. Our cooperation is comprehensive, covering innovation, research and development, production and services – complete product lifecycle management,” Herrmann concluded.