Catalytic iron tech in industrial wastewater treatment

chinagate.cn, March 23, 2015 Adjust font size:

From July to September 2014, Tongji University made a survey on typical sewage treatment process in South China including Zhejiang Province, Jiangsu Province, Hubei Province, Guangdong Provinces, Shanghai Municipality and Guangxi Autonomous Region. The survey is mainly about industrial and municipal wastewater treatment, sludge treatment and disposal, and sewage treatment equipment. a report entitled "Technical report on typical wastewater treatment in the south of China" was issued recently, to identify the appropriate technologies which have potential to be adopted in African countries and other developing countries.

Introduction of catalytic iron technology

In the process of constructing the primary cell, cheap elemental metals (e.g. iron, aluminum) form the anode electrode under the catalytic of cathode metal, refractory organics in wastewater is reduced and its biodegradability is being improved. Forming iron (aluminum) ions is also produces coagulation to strengthen the performance of settling properties of subsequent activated sludge and biofilm process. Catalytic reduction technology can directly reduce the color of wastewater and remove COD by coagulation. Catalytic reduction technology can directly reduce the color of wastewater, and COD is removed by coagulation. While combined with subsequent biological treatment, catalytic iron technology has high efficiency of phosphorus removal, and also provides the nitrification conditions which can greatly improves nitrogen removal efficiency.

Improved aeration process with catalytic iron is further development of this method, which can attribute to coagulation. Shortcut nitrification-denitrification occurs by using catalytic process with iron combined with biodegradation. The technology is simple, stable, low energy consumption. Because of using iron shavings as the material of catalyzed iron inner electrolysis process, the cost is low and there is no secondary pollution. It played a good complementary and coupling role with biochemical method, which can be as a feasible method for industrial wastewater treatment.

Catalyzed iron inner electrolysis equipment

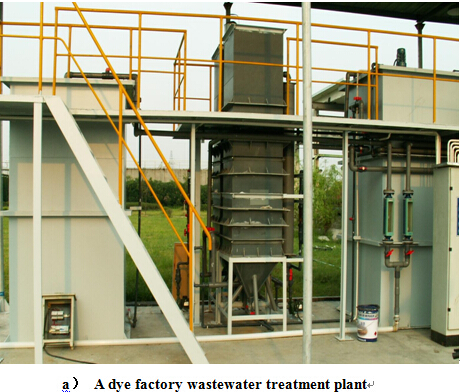

Catalyzed iron inner electrolysis method has an ideal result for biochemical pretreatment and color removal of dyeing wastewater, pulp and paper effluent and other wastewater. For industrial wastewater discharge which is only hundreds of cubic meters per day, treatment units is manufactured in factory and then install on site. For the small amounts of water, the upward-stream reactor can be used to promote water distribution and slag dropping. For the larger amounts of water, horizontal-flow reactor can be used to reduce the height of the device. However, the fluid simulation shows that upward-flow reactor make water distribution more even. Now unitized filter material is coordinated with upward-flow pattern, resistance is generally distributed evenly, short-circuiting current basically does not exist and flow turbulent in all parts can generally ensure interfacial mass transfer effect. Figure 1 shows Catalyzed iron inner electrolysis equipment which treats 50 m3 dyeing water per day, Taopu sewage treatment plant use this kind of reactor equipment.