Gao Zongyu: Engineer and Designer of World-class Bridges

China Today by Zhou Lin, October 13, 2016 Adjust font size:

Innovation Despite Skepticism

The “Construction methodology for rail-cum-road cable-stayed steel bridge of triple main trusses & cable planes” was first applied to construction of the Wuhan Tianxingzhou Rail-cum-road Yangtze River Bridge. This was a milestone in Gao Zongyu’s engineering career.

Tianxingzhou Bridge was awarded the George S. Richardson Medal at the 27th International Bridge Conference in 2010.

The structure of rail-cum-road bridges is usually one whereby vehicles drive above and trains run below. It is a far more complex design than that of a standard highway bridge because the weight of one train is equal to that of traffic on an eight-lane highway. Tianxingzhou Bridge was initially designed as a double-line railway. It then expanded to a triple-line railway, and then to a four-line railway with a six-lane highway, the total load of which was equal to that of a 34-lane highway.

Gao Zongyu holds that the success of Tianxingzhou Bridge lay in innovation, but the path to it was rocky.

Tianxingzhou Bridge was at that time the world’s longest span rail-cum-road cable-stayed steel bridge, and also the world’s first rail-cum-road bridge with a four-line railway. To build a conventional cable-stayed bridge with two cable planes, engineers needed to heighten the bridge as a whole and use even larger steel girders to strengthen the bridge framework.

Gao Zongyu and his team proposed adding one more cable plane and another main truss to enhance the bridge’s rigidity and load-carrying capacity.

This idea, however, immediately sparked searching questions from certain experts. They objected on the grounds that there had been no successful precedents; that the added cable plane would necessitate a more complicated structure whose stress would be hard to calculate; and that there were too many docking points for a cantilever installation, which would pose big construction challenges and risks.

Whether or not the new design was feasible depended on estimating the changes in stress as a result of adding another cable plane to the bridge.

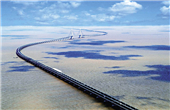

Yingwuzhou Bridge in Wuhan, the world’s first four-span suspension bridge with triple pylons and steel-concrete composite stiffening girders.

How was it possible to analyze and calculate the bridge stress? Taking into consideration Tianxingzhou Bridge’s double decks for three kinds of vehicles – automobiles, freight trains, and high-speed trains – Gao Zongyu and his team independently developed 3D bridge design software to collect and analyze data through simulating traffic. The team spent six months carrying out tests and making calculations. They reached the unexpected conclusion that the added middle main truss bore the same weight as the other two trusses, there being a less than 10 percent difference. This overturned the prevailing opinions and endorsed the new design.

Although everything had been proved in theory, some experts still harbored doubts about putting this theory into practice. Gao Zongyu and his team again did their utmost to find a solution. After working day and night, they finally developed a 700-ton-load automatic girder-erection crane to ensure the trusses’ precise positioning and assembly.

The new design was obviously both economical and feasible – it could potentially save 3,330 tons of steel as compared to the original plan. This was due to the highway and railway docks being one meter lower, which meant that the length of the two approach bridges on either side could be reduced, thus saving more than RMB 110 million in construction costs.

Gao Zongyu holds that innovation is necessary to overcome engineering difficulties. “We innovate to meet engineering needs rather than to try something novel.”